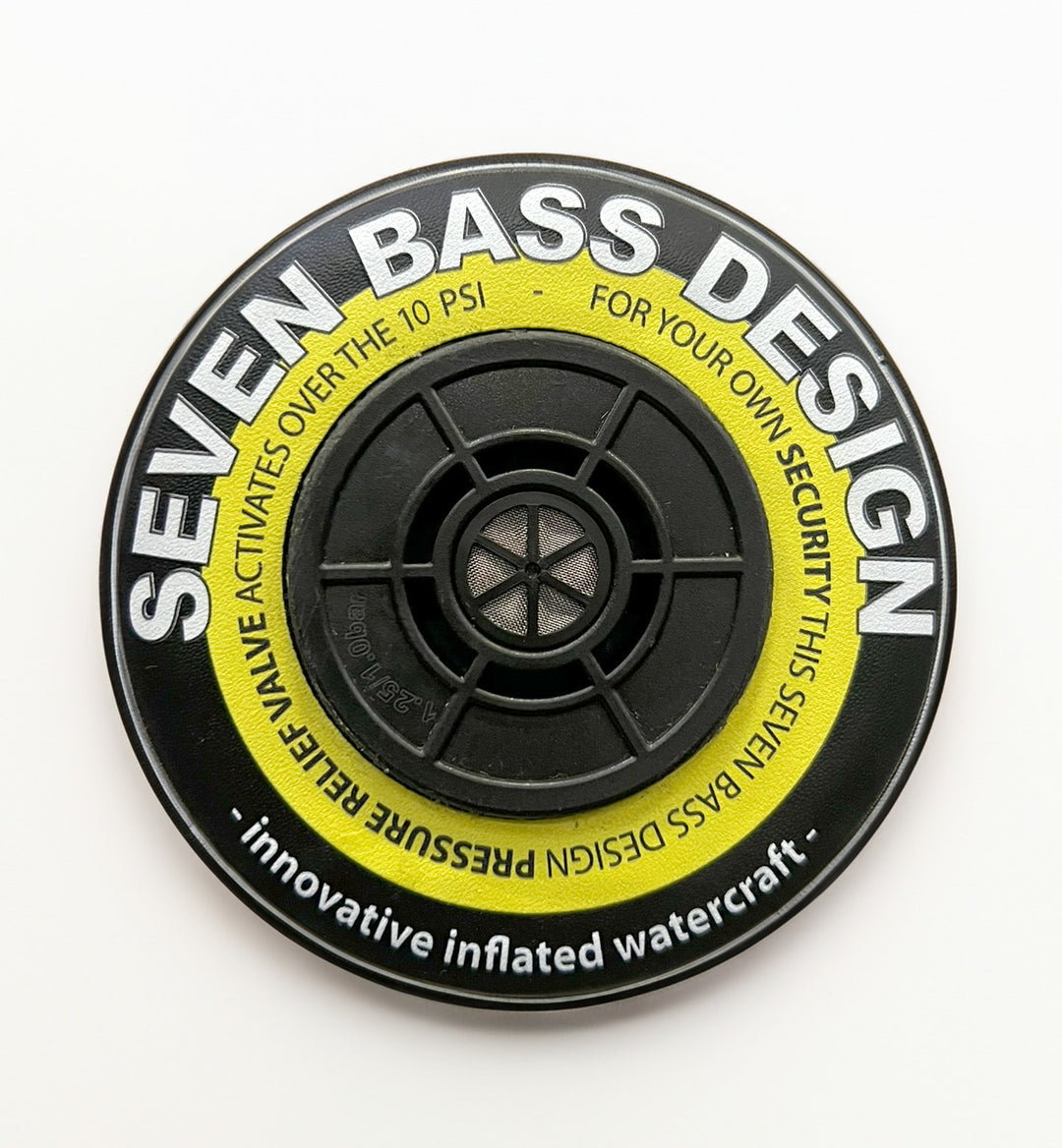

RELIEF Valve Concept

SEVEN BASS DESIGN Relief Valve Technology: Protection, Safety, Peace of mind

With a view to innovation and reliability, SEVEN BASS DESIGN now equips its entire new Dropstitch range with Relief Valve , also called overpressure valve or discharge valve . This device is a key element in ensuring the durability and safety of your float tube, in particular by preventing damage caused by excessive pressure .

Dropstitch inflatables are designed to provide exceptional rigidity and optimum performance on the water. However, like any inflatable equipment, they are sensitive to pressure variations , which can be induced by several external factors. The Relief Valve acts as an automatic safety valve , regulating the internal pressure and avoiding structural problems that could compromise your experience on the water.

Specially designed to work in perfect synergy with MONOCORE technology. Unlike the Stand Up Paddle on the market, which can tolerate higher pressures (11 to 15 PSI), our MONOCORE design optimizes rigidity and load distribution from 10 PSI maximum . Our Relief Valves are therefore calibrated exclusively for this pressure, guaranteeing optimal protection without the risk of overpressure.

The advantage of the MONOCORE & RELIEF VALVE duo

Thanks to MONOCORE technology, SEVEN BASS DESIGN float tubes have a more rigid and resistant single-block internal structure . Unlike conventional designs that require high pressures to achieve correct rigidity, MONOCORE ensures optimum rigidity from 10 PSI .

Our Relief Valves are specifically tuned to work with this system. They ensure that the pressure never exceeds this threshold, thus preserving the integrity of the structure and the longevity of the float tube .

Why is a Relief Valve essential?

One of the main challenges of Dropstitch float tubes is the management of internal pressure , which is essential for the safety and durability of the material. The trapped air reacts to variations in temperature, sunlight and altitude , which can cause overpressure.

Prolonged exposure to sunlight or excessive inflation weakens the structure, which can lead to deformation or detachment of the welds. Conversely, too low a pressure reduces rigidity and impairs performance. Precise control and a suitable safety device are therefore essential to protect the float tube and guarantee its longevity.

Factors influencing internal pressure:

✅ Temperature variations : A float tube left in direct sunlight can quickly see its internal pressure increase. Indeed, under the effect of heat, the air expands , which increases the pressure exerted on the walls of the float tube. Conversely, sudden cooling can cause a drop in pressure , impacting the rigidity of the boat.

✅ Over-inflation : Too high a pressure from the start weakens the welds and the assembly of the MONOCORE . Prolonged overpressure can lead to deformation, loss of sealing, or even sudden rupture of the float tube.

✅ Altitude changes : If you transport your float tube by car to a mountainous area or an area where the altitude varies, the atmospheric pressure decreases with altitude , which can affect the internal balance of the float tube.

✅ Intensive use and impacts : A float tube regularly used with heavy loads or subjected to repeated shocks can also see its structure weakened by poorly distributed internal tensions.

Without an effective regulation system , these factors could prematurely deteriorate your equipment , reducing its lifespan and compromising user safety.

How the Relief Valve Works

The Relief Valve is a valve designed to automatically release excess pressure when it exceeds a set threshold.

How does it work?

🔹 Passive and continuous monitoring : The Relief Valve is always in working order. It constantly monitors the internal pressure of the float tube and reacts instantly if it exceeds a critical limit.

🔹 Automatic opening in case of overpressure : As soon as the pressure reaches a predefined threshold of 10 PSI , the Relief Valve opens automatically and gradually releases air.

🔹 Restoration of optimal pressure : Once the pressure has returned to a safe level, the valve closes automatically , thus preventing any excessive air loss.

🔹 Fully autonomous system : No manipulation on your part is required. You do not need to intervene to open or close the valve, which guarantees optimal safety in all circumstances.

This mechanism thus ensures effective and instantaneous regulation of the internal pressure, considerably reducing the risks of premature degradation of the float tube.

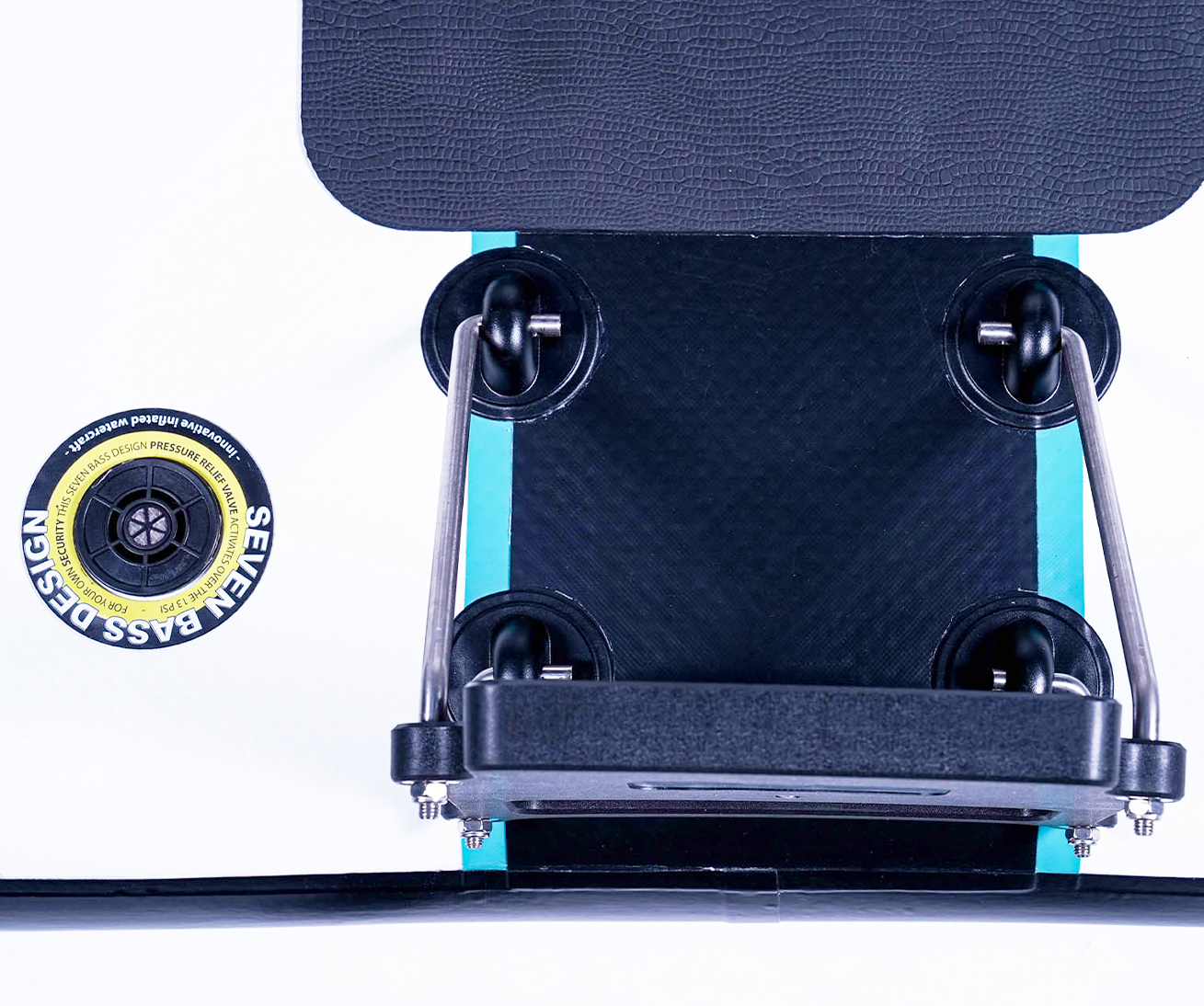

Where is the Relief Valve located on a Dropstitch float tube?

The Relief Valve is strategically placed on the float tube to provide maximum efficiency. Its positioning depends on the design of the model, but it is generally installed:

🔸 Near the main inflation valve : This position allows optimal control of the pressure in relation to inflation and facilitates maintenance.

🔸 On the rear deck on the surface of the float tube : A more accessible position allows rapid release of excess air and better air circulation inside the structure.

Each SEVEN BASS DESIGN model has been designed with a precise study of the ideal location of the Relief Valve, thus guaranteeing optimal efficiency and responsiveness.

Maintenance and best practices to optimize the life of your Relief Valve

Although the Relief Valve is a self-contained and reliable system, regular maintenance is recommended to ensure proper operation and to avoid any obstruction that could affect its effectiveness.

Care instructions:

✅ Rinse after each outing : After a fishing session, especially in salt or muddy water, it is essential to rinse the valve with clean water to remove deposits of salt, sand or debris that could hinder its operation.

✅ Periodic inspection : Check that the valve is not blocked and that there is no residue preventing its proper operation.

✅ Storage in good conditions : If you leave your float tube inflated for a long period, remember to deflate slightly in order to minimize tension on the structure and avoid prolonged activation of the valve.

✅ Protection against extreme temperatures : Although the Relief Valve protects against overpressure, it is advisable to avoid prolonged exposure to intense sunlight or very low temperatures which could alter the performance of the materials.

Good reflexes to preserve your Dropstitch float tube

Even with the advanced technology of the Relief Valve , adopting good practices on a daily basis will help you optimize the performance and longevity of your equipment:

✔️ Do not leave your float tube in direct sunlight for too long : Even if the Relief Valve limits overpressure, it is best to avoid excessive exposure to direct sunlight.

✔️ Respect the recommended inflation pressure : Use a pump with a pressure gauge to ensure precise pressure and avoid overloading your float tube.

✔️ Store your float tube correctly : If you have to leave it inflated for a long time, remember to deflate it slightly to avoid unnecessary tension on the structure.

An innovation for sailing with complete peace of mind

Thanks to the Relief Valve , SEVEN BASS DESIGN Dropstitch float tubes benefit from advanced protection against overpressure , thus guaranteeing safety, longevity and performance .

This smart technology allows you to focus fully on your experience on the water , eliminating the risks associated with pressure variations and providing complete peace of mind .

Whether you fish in a river, lake or sea, your float tube is designed to accompany you for a long time on all your aquatic adventures!