OUR FACTORY

SEVENBASS DESIGN invests in its own factory: a strong commitment to excellence and sustainability

At SEVEN BASS DESIGN, we are proud to announce our investment in our own factory, a modern and eco-friendly facility that allows us to control our entire production process.

As the only float tubes brand in the world to have it's own factory entirely dedicated to the manufacturing of our products, we affirm our commitment to producing responsibly, sustainably and with high quality.

A strategic location for reduced impact

Located close to Europe, our factory benefits from a strategic location that allows us to significantly reduce our carbon footprint compared to traditional transport methods from Asia. This geographical proximity allows us to guarantee fast delivery times while minimizing the environmental impact linked to transport. This approach is fully in line with our CSR strategy, integrating sustainable practices at each stage of our value chain.

Quality and eco-responsibility standards

Our factory complies with all applicable ISO standards for the production of PVC and Dropstitch inflatable products, including ISO 9001, which attests to our commitment to quality and continuous improvement. We firmly believe that quality should not come at the expense of the environment. That is why we use premium materials and adopt environmentally friendly manufacturing practices.

Each batch of glues and raw materials, whether PVC or Dropstitch, is systematically tested by independent laboratories before use. These tests ensure that all our components meet rigorous performance and safety criteria, reinforcing our quality promise.

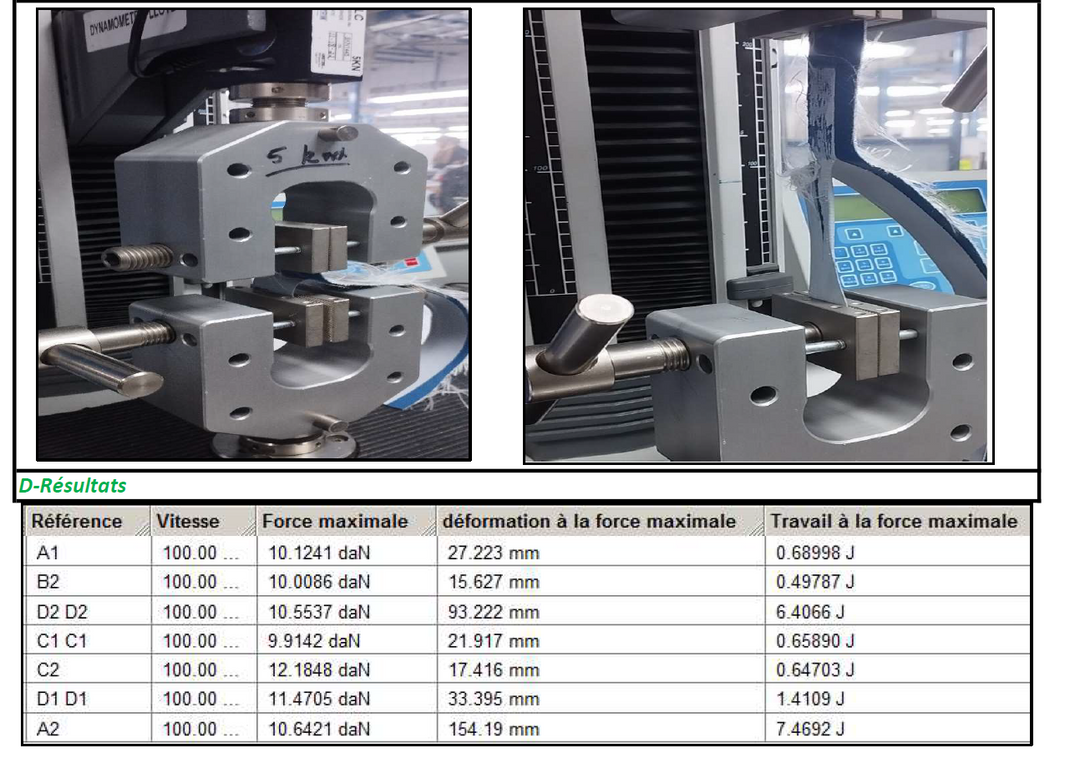

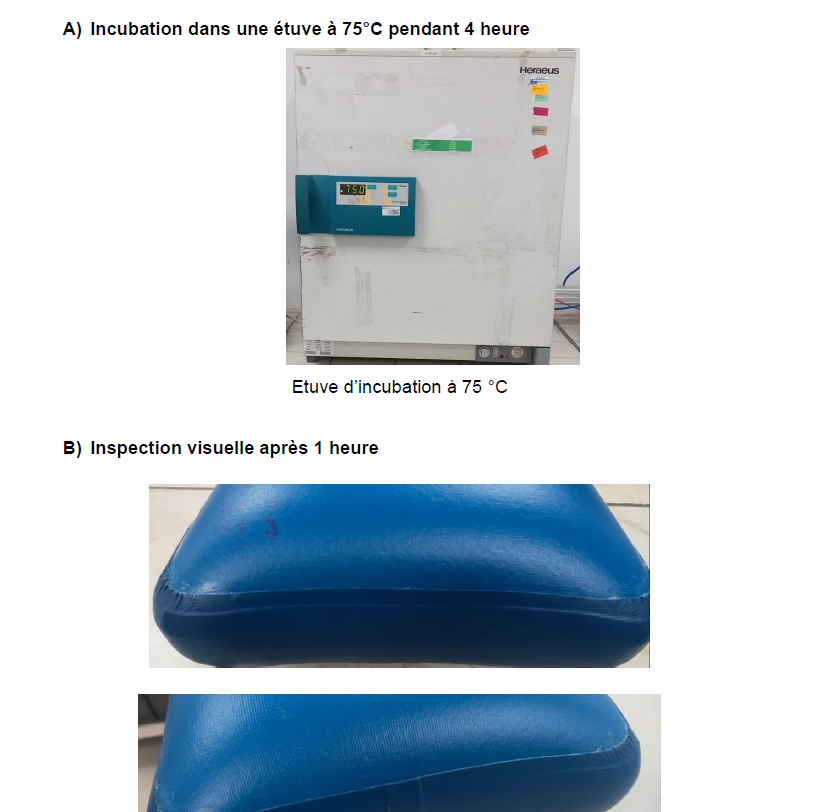

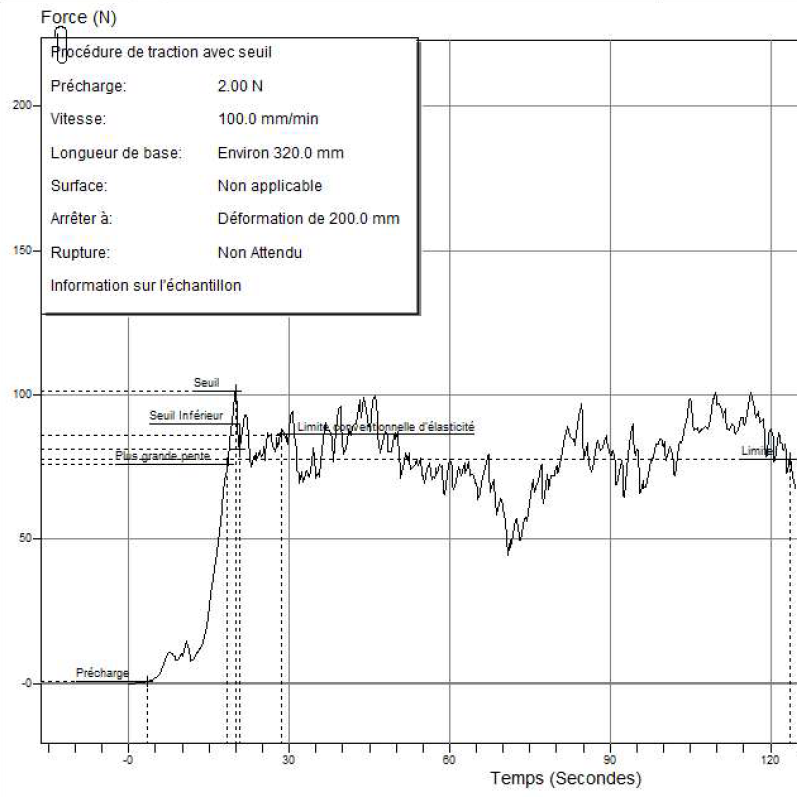

Rigorous testing and quality control

To maintain our level of excellence, we conduct rigorous tests on our products every week. These evaluations include heat, tear and peel resistance tests, carried out by accredited independent laboratories. This approach allows us to guarantee the reliability and durability of our products, while meeting the highest certified standards in the industry.

All our products also have a unique tracking number, which allows us to identify the operators who contributed to the manufacturing of your product, as well as all batches of raw materials used. This traceability ensures total transparency on our production process, reinforcing the confidence of our customers.

State-of-the-art equipment

We use state-of-the-art equipment to ensure accuracy and efficiency in our manufacturing process. Our laser cutting tables ensure precise cutting, reducing material waste. In addition, our world-renowned printers are designed to provide high-quality UV printing on PVC, using environmentally friendly inks.

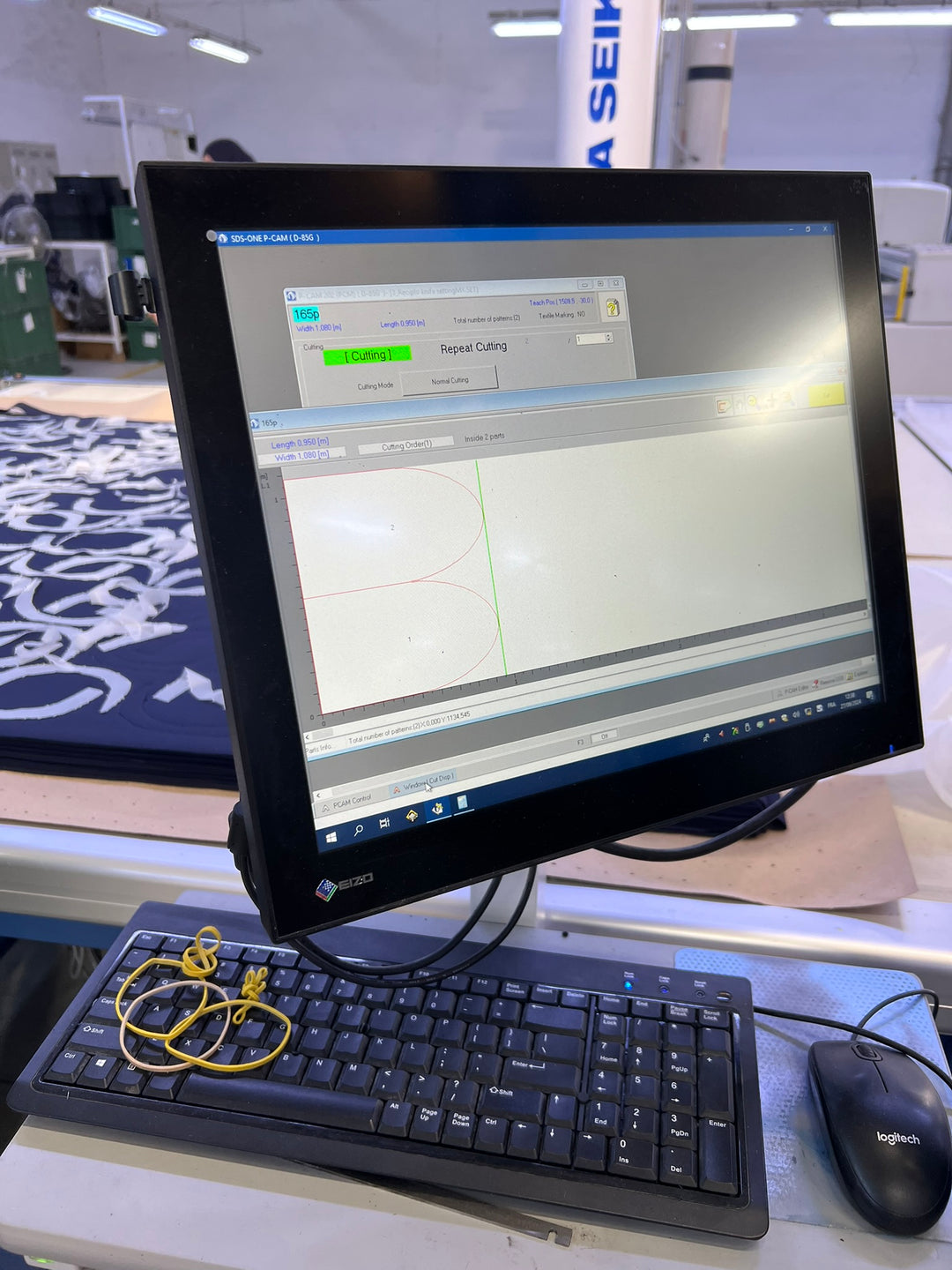

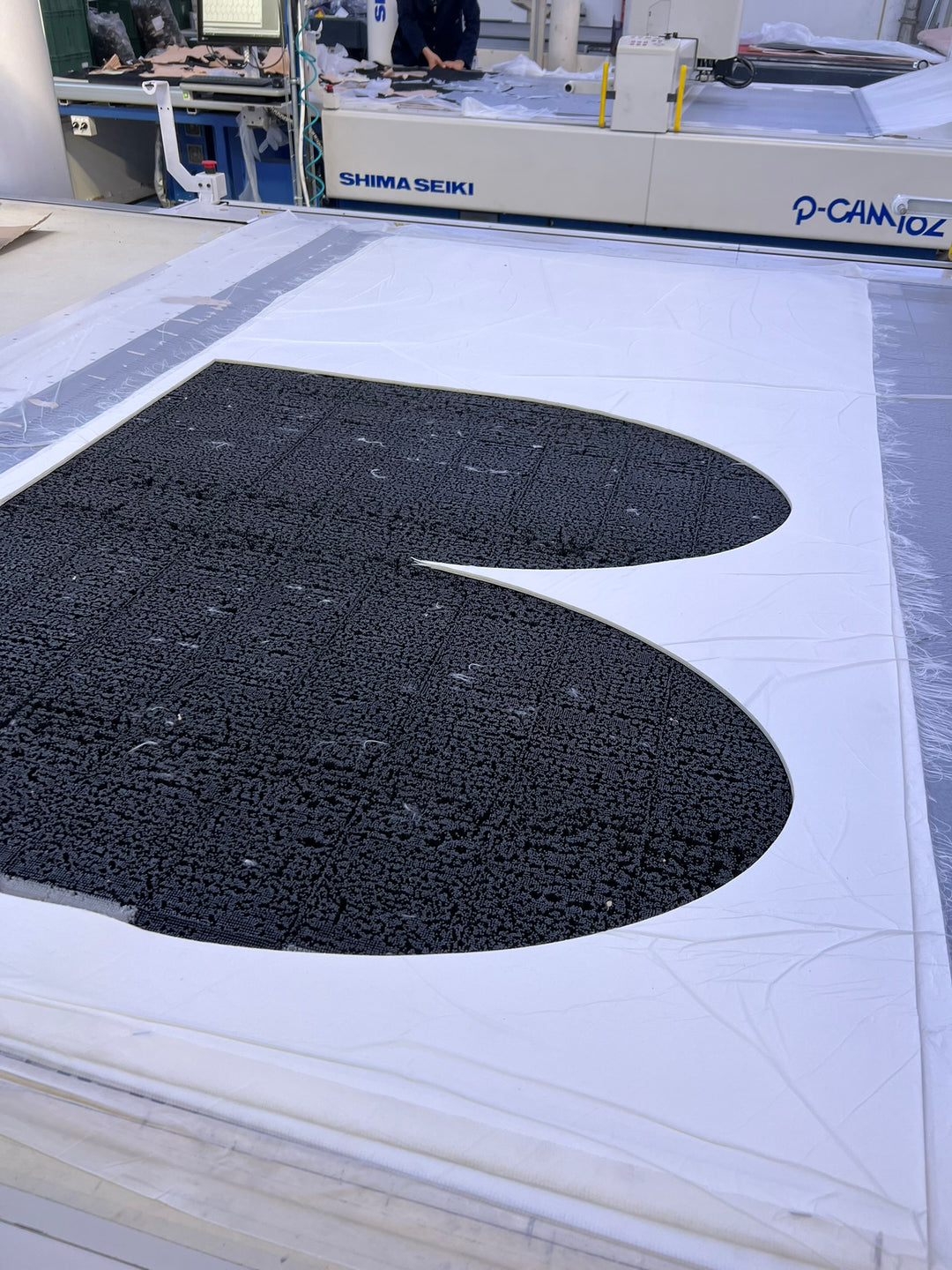

CNC Cutting

SEVEN BASS DESIGN continues to push the boundaries of innovation with the integration of CNC cutting in its new high-tech factory, equipped with the most advanced technologies. Unlike laser cutting, CNC cutting (Computer Numerical Control) offers enhanced precision and great flexibility in the manufacturing of our products. This process uses numerically controlled machines to cut materials such as PVC and DROPSTITCH, two key elements in the design of our equipment.

The main advantage of CNC cutting lies in its ability to perform complex cuts with micrometric precision, ensuring perfect finishes and unmatched dimensional accuracy. This process is not only faster but also allows for working with a wider variety of materials and shapes, offering advanced customization for each product. Additionally, CNC cutting optimizes material usage, reducing waste and making production even more eco-friendly.

By adopting CNC cutting, SEVEN BASS DESIGN ensures superior quality and increased performance in its products, while meeting the demands of the most discerning anglers and adventurers.

UV printing

At SEVEN BASS DESIGN, we use the latest generation of UV printers to produce high-quality prints on our PVC products. This advanced technology allows us to print logos, valve decorations and customised personalisations with exceptional precision, meeting the specific expectations of our customers. Thanks to UV printing, the colours are vibrant, durable and resistant to the most extreme conditions, whether in fresh or salt water. This process also offers the possibility of applying unique finishes, such as camouflage patterns, while maintaining the integrity of the material. By combining the robustness of PVC with the finesse and durability of UV prints, we create products that are both aesthetic and high-performance, designed to withstand wear and tear while offering maximum customisation.

Eco-friendly packaging

We are also committed to sustainable packaging practices. All of our products are packaged in a way that minimizes plastic waste, and we prioritize the use of recyclable and reusable materials. Every aspect of our supply chain is designed to be greener, from product design to final delivery. By taking an eco-friendly approach to our packaging, we are helping to reduce waste and protect our environment.

An eco-responsible future

This investment marks a crucial step in our journey, allowing us to continue to innovate while strengthening our commitment to the environment and our customers. With this plant, we are determined to offer superior quality products that meet the expectations of modern fishermen while respecting our planet. Our eco-responsible approach is anchored in our identity and our mission, because we believe that it is possible to reconcile performance, quality and respect for the environment.

In short, at SEVEN BASS DESIGN, we don’t just produce float tubes; we create products that reflect our commitment to sustainable and responsible fishing. Together, we can contribute to a future where the passion for fishing is in harmony with the preservation of our environment.